United Valve – Repair,

Modification & Testing

Industry-Leading Valve Services Since 1961

Through alliances and partnerships with over 40 of the world’s top valve manufacturers, United Valve provides factory and OEM authorized valve services for a broad spectrum of distributors and end-users around the globe.

Our 104,000 sq. ft. Houston facility is in the heart of the Texas refining and petrochemical belt. Our Corpus Christi facility serves customers in the lower Gulf Coast area. All work is performed by an experienced staff of technicians and craftsmen, led by a team of degreed engineers.

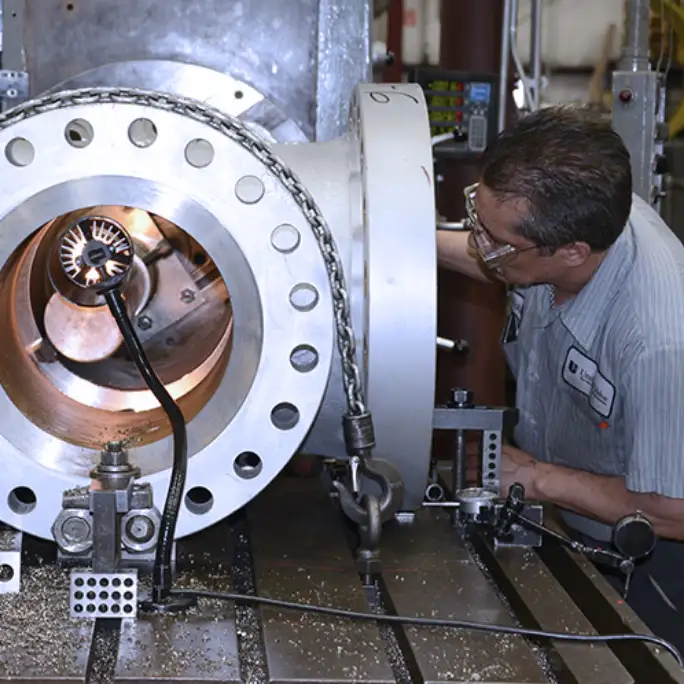

The Houston plant is equipped with state-of-the-art machining, welding, pressure testing, and non-destructive evaluation equipment. From X-ray radiography to multi-axis CNC machining centers, United Valve is vertically integrated to handle virtually any type of valve service in-house. Materials handling capabilities include eight overhead bridge cranes with a maximum hook height of 37 feet. Crane capacities range to 40 tons. We have many years of experience in industrial valve services.

United Valve employs experienced valve service technicians that can diagnose and perform industrial valve repair for virtually all types and sizes including gate, globe, check, and ball valves. A vertically integrated shop environment allows us to routinely perform operations that other valve service companies have to outsource.

We repair all sizes and types of standard and commodity valves, as well as specialty valves such as:

- Coker ball

- Large diameter

- High-pressure flanged

- Butt weld end (BWE)

- HP power plant

United Valve specializes in engineered valve modification work. We have five CNC machine tools as well as numerous manual machines allowing us to rapidly machine valve trim components of any size and out of any material, whether standard or exotic metallurgy. Cryogenic valve modification is one of our specialties, and we have produced hundreds of valves for low temperature applications.

Some of the many modification options we provide include:

- Casting Upgrades

- Cryogenic Valve Fabrication

- Fabrication Work

- Packing & Gasket Changes

- Trim Change – All Alloys & Base Materials

United Valve is a leading pioneer in industrial valve testing, including valve fire testing, known for our dedication to continuous improvement and innovation. We have helped develop widely adopted testing standards, ensuring durable and efficient products. With a wide range of testing machinery and equipment in our shop, we can conduct testing on almost any type or size of valve in-house.

A few of the standard testing services we offer are:

- Fugitive emissions

- Cryogenic testing

- Radiography

- Positive Material Identification

- Hydrostatic

Depend on us for exceptional industrial valve repair, modification, and testing services. Our team of skilled technicians are dedicated to providing high-quality solutions for all your valve service needs. With years of industry experience and a commitment to customer satisfaction, we ensure that your valves are in optimal condition.

Trust United Valve for reliable and comprehensive valve services that exceed expectations. Contact our experienced team now.